Welcome to the first edition of The Supply Chain Roundup! Supply Chains, Logistics, and Material Handling are changing so fast it’s hard to keep up. There’s a firehose of information blasting at us every day–so we’ve curated the most interesting and valuable things we read into this monthly roundup. If you’d like to sign up to get it monthly via email, please subscribe!

Someone pointed out there are only three more months until 2022, so enjoy these first few days of fall as peak retail season arrives!

Ryan Lynch

VP of Marketing

Supply Chain Insights

News from around the Industry

Innovative thinking for Employees

How two companies are using pay increases to address the labor shortage:

- An Ohio factory owner had wondered if higher wages would ease staffing shortages or push him into the red. He used his PPP loan to find out–and so far, it seems to be paying off.

- As Walmart ramps up for the holidays, it is paying bonuses to employees who work every scheduled hour and, in some cases, is awarding temporary pay raises.

Cool Stuff

Great to see the supply chain used for good–the 5,000 medals for the Tokyo Olympics were created using 78,985 tons of recycled electronic devices, including cell phones. Urban mining is a sustainability effort that helps reclaim otherwise highly toxic e-waste.

Chewy recently sent someone flowers after she called their customer service line to cancel a standing order because she had to put her elderly dog to sleep. This is an incredible example of out-of-the-box thinking, and while it’s obviously a loyalty-generating technique, it works because it also feels genuine and empathetic.

Supply Chain

- Walmart and other goliaths have pushed holiday shipping forward two months, a signal you should ACT NOW on ordering to avoid bottlenecks, if you haven’t already. Some products have a total shipping time (cargo-ready date to in-distribution center date) of over 100 days, which was previously unheard of. Read Warning: Book Now or Christmas May Be Canceled!As this article points out, you can pay or you can wait for global shipping–but even paying more isn’t a guarantee your goods will make it on time.

- Why New Books Will Be Hard to Come By for the Rest of the Year explains–well, you guessed it. The article’s linked Twitter thread from independent bookstore Tubby & Coo’s Mid-City Book Shop is a great mini-tutorial that explains just how complex the supply chain really is.

- Here’s a recent video Concentric did on How to Prepare for Supply Chain Volatility in 2021–and Beyond. Check it out!

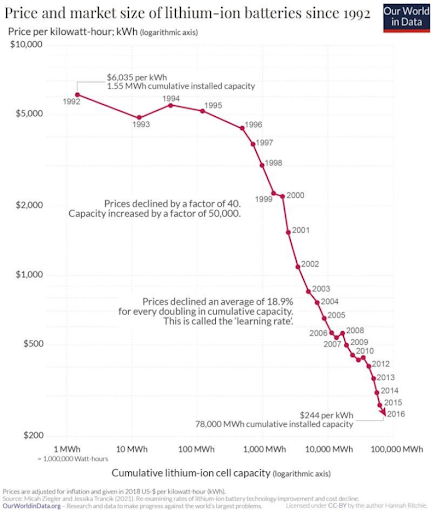

Forklift Power

An interesting graphic on why lithium is now a viable option for a growing number of material handling (forklifts, etc) applications.

Automation

Although this article suggests that small and medium sized companies aren’t using lots of robots, robots/cobots that can drop into existing facilities may provide a competitive edge. It’s one of the ways mid-tier players will be able to keep up with the Home Depots and Wal-Marts that drop a new automated DC every quarter or month.

That said, facilities have to first realize that optimizing their material flow and existing equipment/approach is critical to sustaining competitive advantage.

Here’s some interesting thinking in Forbes from Steve Banker. How will warehouse design change with the increased focus on automation?

1. Air-conditioning for workers – The main warehouse area would be populated by robots for all depositing and picking of items from racking/pallets. A smaller area could be sectioned off as a smaller pick station area for humans to collect the items from the robots. This smaller area would have automated doors for the robots and air conditioning for the workers.

2. Warehouse heights may shrink – Warehouses would shrink in height, since typical robots can only pick up to eight feet. They also can’t run on a second-floor mezzanine, as it has a wired/choppy floor.

Smart Ideas from Smart People

“A great deal more fiction is written in Excel than in Word” – Unknown

Resource of the Month

From the TFS Team

10 Tips to Manage Long Lead Times on Material Handling Assets

Forklift delivery lead times have exploded this year with no end in sight. Here are 10 strategies our Account Executives are implementing with customers across America to ensure you mitigate downtime and cost risks during a time of increased volatility.